An outbreak caused by Salmonella Kiambu has been linked to dry pet food products distributed nationally. Seven cases of illness affecting mainly children aged one year or less have been reported from multiple states since January 2023. Retail product collected for routine testing by the South Carolina State Department of Agriculture was found positive for Salmonella and determined to be closely related to the outbreak strain utilizing whole genome sequencing. This finding led to a nationwide recall of several brands of dry kibble produced at the manufacturing facility with a best by date before 10/31/2024. While outbreaks associated with dry kibble products are infrequent, this new outbreak highlights the challenges associated with dry pet food production and the persistence of Salmonella in low moisture products.

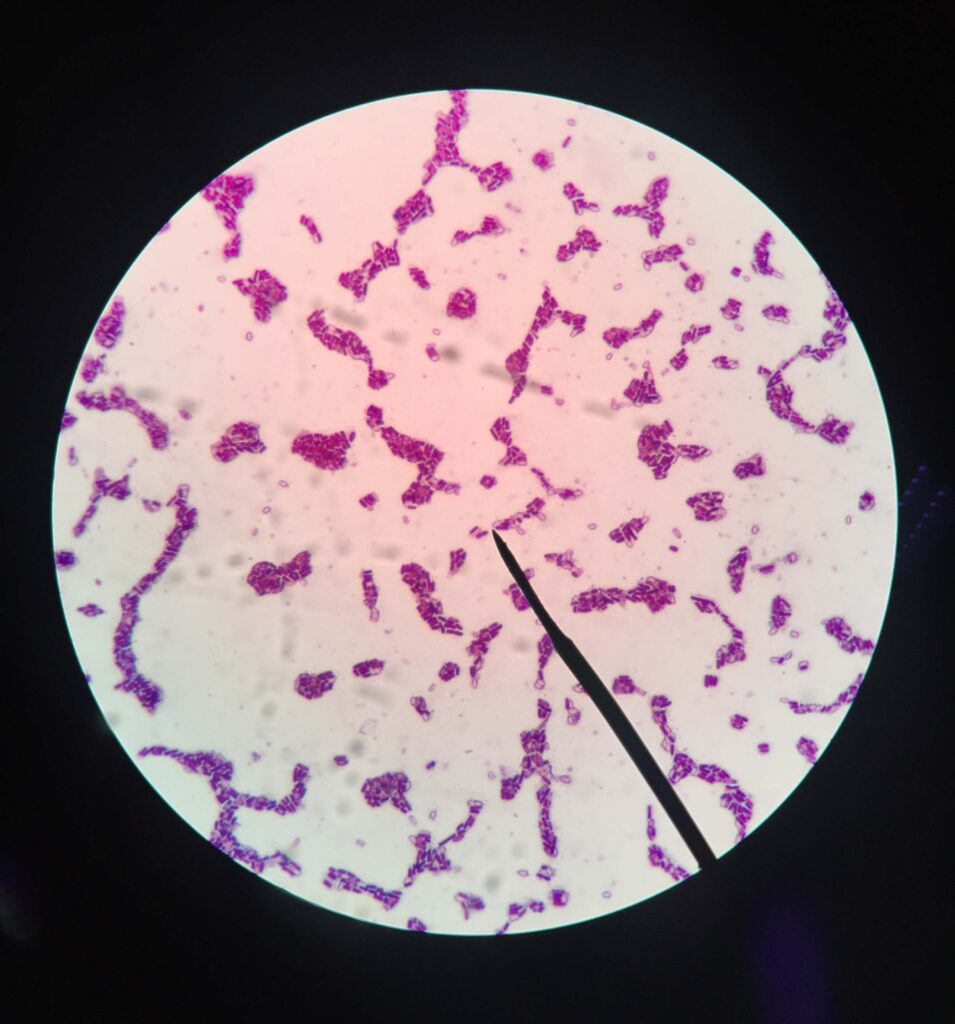

Salmonella is readily found in the ingredients (e.g. rendered animal byproducts and grains) used to make pet food kibble. However, thermal extrusion processes used to make kibble are generally lethal to this organism. Liquid water and/or steam is added to the dry ingredients that are pushed through the barrel of an extruder under intense heat and pressure before exiting through a shaping die. The extrusion process is often validated as a process preventive control to reduce vegetative pathogens by a minimum of 5 logs. Product is then dried resulting in a shelf stable product with a water activity (aw) <0.60.

The low aw prevents pathogen outgrowth but not pathogen persistence if reintroduced after the extrusion step. Product can be re-contaminated from the environment or from the addition of ingredients such as fat and flavorings that are sprayed on the dried kibble to enhance palatability. Post-extrusion contamination likely led to the last major Salmonella outbreak involving kibble that occurred between 2006-2007. During the investigation of this previous outbreak, the same Salmonella serotype was found in the pet food manufacturing environment as well as in two of the 25 brands of pet food produced at the facility. The only positive environmental sample was found in the enrobing/flavoring room where product was coated with a palatant after extrusion. Because the extrusion process utilized time/temperature parameters validated to kill Salmonella, it was thought that cross-contamination of the extruded kibble occurred from contaminated ingredients or environmental contamination during the enrobing/flavoring process.

Supply chain controls can mitigate hazards associated with ingredients added after the extrusion process. Hygiene and sanitation controls can mitigate hazards introduced post extrusion when verified with a robust environmental monitoring program. Pathogen testing should include line samples and environmental samples including air filters, equipment, vents, and drains. Guidance is available from FDA for the safe production of pet food. Deibel Laboratories can provide full service solutions from environmental assessments of facilities to finished product testing for pathogens and indicators as well as validation of nutritional labels for pet foods.