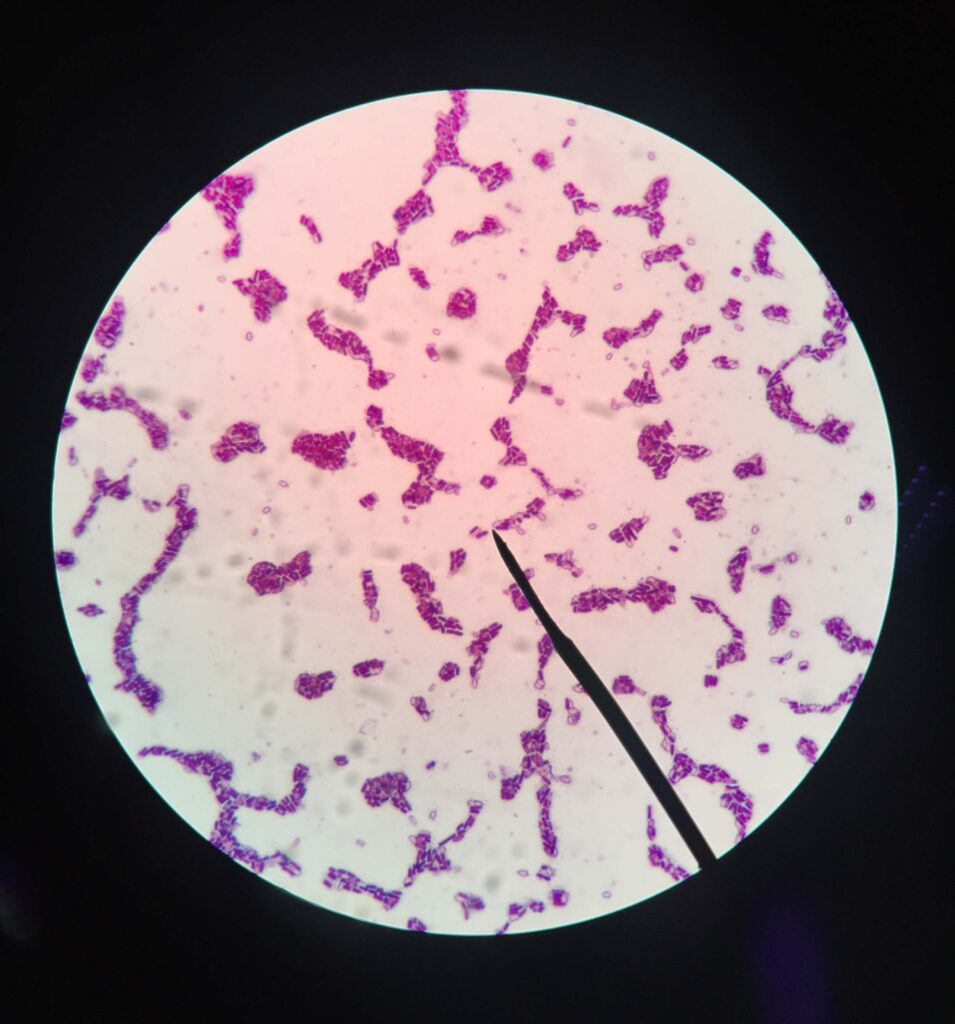

A warning letter was recently issued to a manufacturer of refrigerated ready-to-eat baby food products packaged in a reduced oxygen environment. The investigation that led to the warning letter was initiated because of a consumer complaint that involved a case of infant botulism. Infant botulism is caused by the presence of C. botulinum spores that temporarily colonize an infant’s large intestine and produce botulinum neurotoxin. However, spores are not a hazard for the majority of the population with developed guts. Instead, controlling C. botulinum spore germination, outgrowth, and toxin production in products that can support growth should be the focus of food manufacturers as highlighted by FDA in this warning letter.

In the warning letter, FDA cites that the manufacturer’s hazard analysis did not identify the potential for C. botulinum growth and/or toxin formation due to reduced oxygen packaging. This hazard should have been identified because C. botulinum is associated with the various product ingredients that are grown in the ground. This organism is an anaerobe that can grow in the reduced oxygen packaged product and pose a food safety risk because the product did not undergo a sporicidal treatment and the formulation did not control outgrowth and toxin formation.

Although the product was stored refrigerated, FDA indicated that refrigeration temperatures exceeded the levels necessary to prevent non-proteolytic C. botulinum strain outgrowth, considered to be <3°C. Likewise, the manufacturer did not utilize calibrated temperature probes that often indicated misleading monitored results. When temperature is the only control for C. botulinum, strict monitoring of that control is necessary throughout product storage.

Because temperature control throughout product storage, during transportation, and by the consumer may be hard to maintain, manufacturers will turn to other controls for C. botulinum. This can include a sporicidal heat treatment as outlined in 21 CFR Part 113 (Thermally Processed Low-Acid Foods Packaged In Hermetically Sealed Containers) or formulation and packaging controls that include:

• pH ≤4.6

• Water activity ≤0.935

• Aerobic packaging

• Preservatives such as nitrite, sorbic acid, phenolic antioxidants, polyphosphates, and ascorbates

A hurdle approach, or combination of controls, can also be used. In this case, no single control limits C. botulinum outgrowth. The combination of controls is commonly verified for effectiveness with a challenge study. Testing and handling of many bacterial toxins, like botulism toxin, requires sophisticated laboratory quality controls, including CDC / APHIS select agent accreditation. Deibel Laboratories has select agent approval and can conduct challenge studies to help verify that controls are effective to prevent C. botulinum outgrowth and toxin formation.