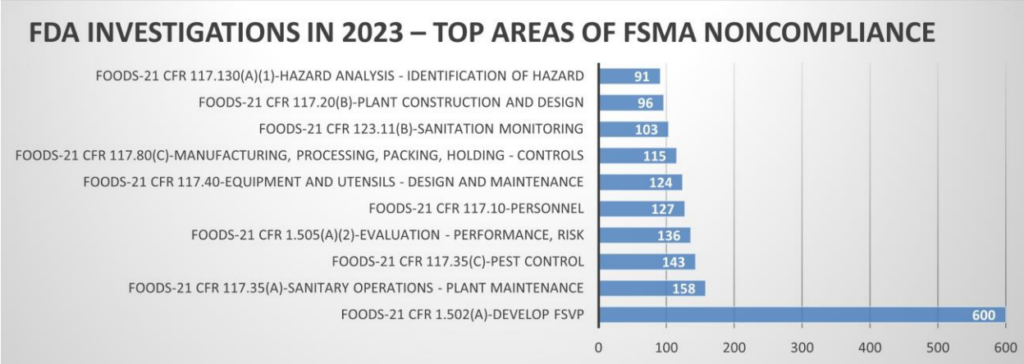

According to FDA’s Data Dashboard, the most frequently cited violation by FDA investigators in fiscal year 2023 (ending September 30th) was the failure to develop an FSVP. This encompassed about 35% of all form 483 citations issued. Additionally, nine warning letters were published in the past month alone when food importers failed to correct FSVP violations cited during FDA investigations. According to FDA data, warning letters issued for FSVP violations in 2023 increased in number from the previous year. Forty-eight importers were placed on import alert and only two were removed. Normally, FDA investigators will determine if foreign food is imported during routine investigations. Manufacturers that import food and lack FSVP documentation will be cited for not following the FSVP rule if no exemptions apply.

Warning letters published this past month cited inaction on developing, maintaining, and following an FSVP as required by section 805 of the FD&C Act and 21 CFR 1.502(a) for any of the foods they import. Generally a written response to a warning letter is required within 15 working days of notification. If the matter is not adequately addressed, the FDA may take further action including an FDA product hold, detention, and Import Alerts (e.g. Import Alert # 99-41). Removal from an Import Alert is a lengthy process. The importer is required to submit information to the FDA that adequately demonstrates resolution of the conditions that gave rise to the FSVP violation and provide assurance that FSVP requirements will be met for future imports.

Final guidance is available from FDA to help importers comply with the FSVP rule. U.S. importers who have responsibility for fulfilling FSMA FSVP requirements for foreign suppliers that manufacture, process, pack, or hold food intended for human or animal consumption in the U.S. must use a qualified individual to develop and perform FSVP activities. These activities include determining known or reasonably

foreseeable hazards associated with each type of food, evaluating risks posed by the supplier’s performance, approving suppliers, conducting appropriate supplier verification activities, and verifying corrective actions that provide assurance the food’s hazards have been significantly minimized or prevented. Detailed records documenting these activities are also required.

A course specifically designed to train FSVP qualified individuals was developed by the Food Safety Preventive Controls Alliance (FSPCA) that provides a standardized curriculum recognized by the FDA. The course is offered by Deibel Laboratories.